Tenan Optoelectronics controls the quality of LED light strips

Contact Name : Manda Lai;Tel : +8618026026352 (wechat/whatsapp);Email : sale@ledtealight.com

1. Select high-quality raw materials to ensure quality foundation

Tenan Optoelectronics is well aware of the importance of raw materials to product quality, so it selects high-quality suppliers around the world and conducts strict random inspections and performance testing of each batch of raw materials. For example, LED chips detect key parameters such as luminous efficiency and color rendering index. In addition, the company has established a supplier evaluation system to conduct regular evaluations and timely communication for rectification or replacement to ensure the stability and reliability of raw material supply.

2. Create excellent quality

The company's workshops are modernized and use industry-leading automation equipment and advanced process technology. The production process follows standardized operating procedures (SOP). For example, a high-precision placement machine is used in the placement process to ensure accurate placement of LED chips, control errors, and ensure the performance and uniformity of the light strips. Workers are professionally trained, have operational experience and quality awareness, and carry out strict self-inspection and mutual inspection to solve quality problems immediately. The company continues to conduct research and development, optimize processes, and improve production efficiency and product quality.

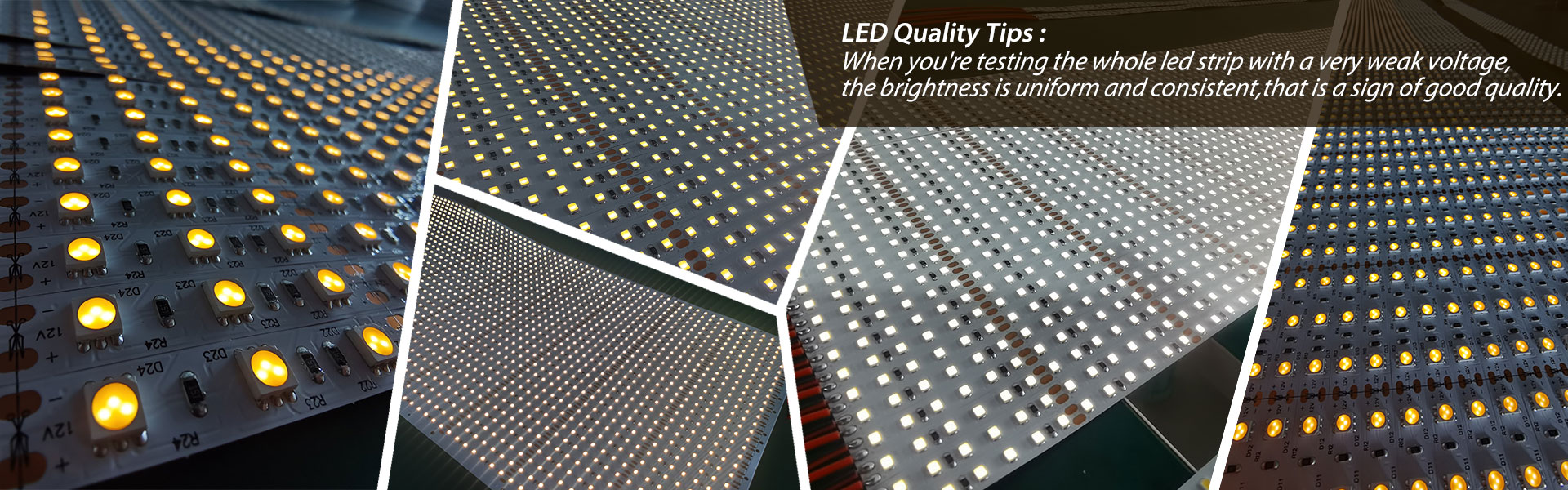

3. Strict quality inspection and strict compliance with quality standards

Tenan Optoelectronics has built a comprehensive quality inspection system, including multiple online inspection processes to monitor the electrical and optical performance and appearance of semi-finished products in real time. Use a spectrum analyzer and electrical performance tester to ensure that the lamp strip specifications meet standards. The finished products undergo full inspection, including aging testing and appearance inspection, to ensure stability and consistency. Only qualified products can enter the packaging process.

4. Intimate after-sales service and continued quality care

The company is customer-centric and provides comprehensive after-sales services. There is a customer service team to handle inquiries, complaints and suggestions in a timely manner. Solve technical problems and after-sales maintenance, and provide product installation instruction manuals and video tutorials. Quick service and strict testing of repaired products to ensure optimal performance. A complete after-sales service system enhances brand image and customer satisfaction.