Choose high-quality LED light strips to see these six points?

Contact Name : Manda Lai;Tel : +8618026026352;Email : sale@ledtealight.com

1. Brand and certification

Choose a well-known light strip manufacturer or brand of LED light strips, and the quality and reliability are usually higher. In addition, make sure that the LED light strips comply with corresponding certification standards, such as CE, ROHS, etc., to ensure their safety and compliance with environmental protection standards.

2. Color accuracy and eye protection

For applications that require specific colors, such as display space or stage lighting, color accuracy is crucial. Check the LED strip’s color temperature and color index (CRI) to make sure it can restore the real color of the object.

3. Cropable and connection distance

Learn whether LED light strips support cropping and connection to meet the needs of different lengths. Some high-quality LED strip designs allow users to cut at specific points without affecting their performance.

4. Brightness and Light Effect

When selecting LED strips, pay attention to their brightness, usually measured in lumens (Lumen). High-brightness LED strips can provide better lighting effects. At the same time, pay attention to the light effect (lm/w), that is, the luminous effect at unit power, and the high-light efficiency LED light strip is more energy-saving.

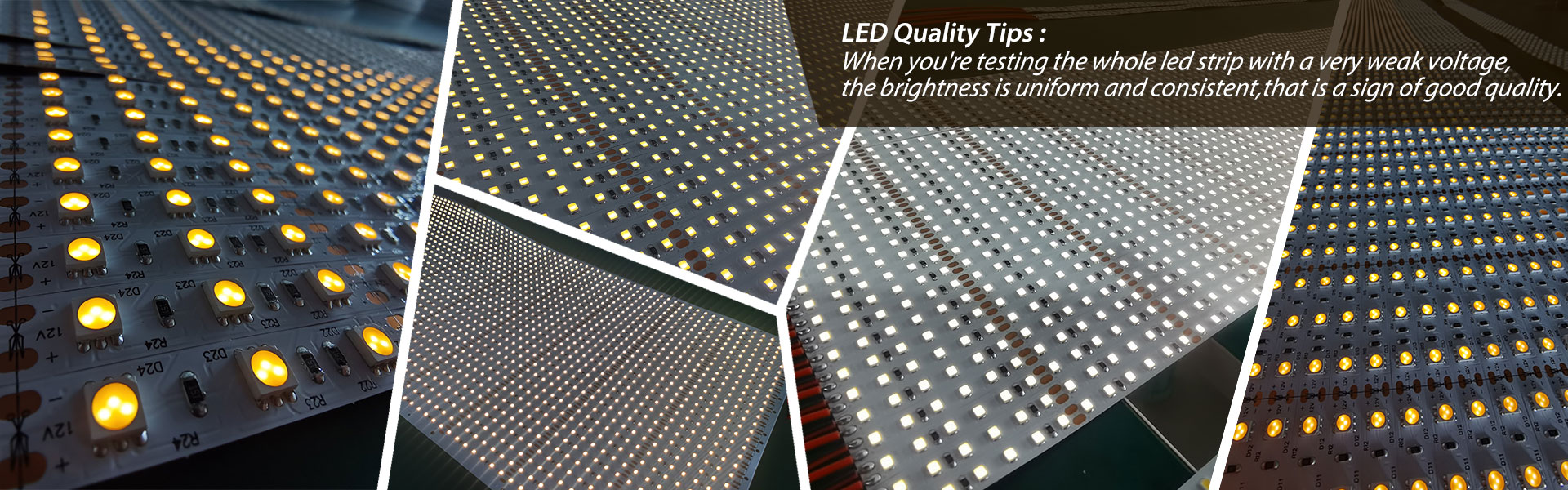

5. Look at the cleanliness of the surface of LED light strip

The surface of LED light strip adopts SMD technology is clean and free of impurities and stains. In contrast, the surface of the hand-welded LED light strip still has stains and traces after cleaning, and flux and materials may remain on the FPC surface.

6. Look at the quality of FPC

FPC is mainly divided into copper foil and calendered copper plate. The copper foil is located on the convex surface of the copper plate and can be seen at the connection between the pad and the FPC. The rolled copper plate is closely combined with the FPC and can be bent without affecting the pad. However, excessive bending of the copper plate or excessive temperature during maintenance may cause the pad to fall off.